Database

Tracking Machinery for Your Business

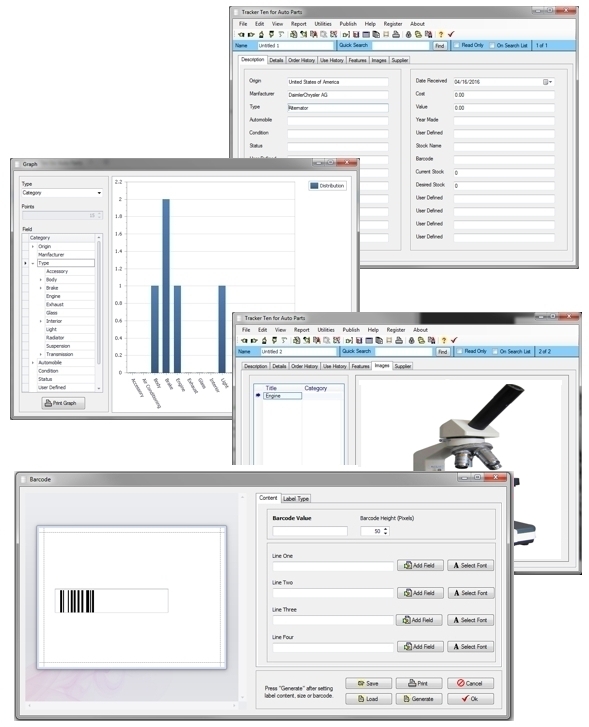

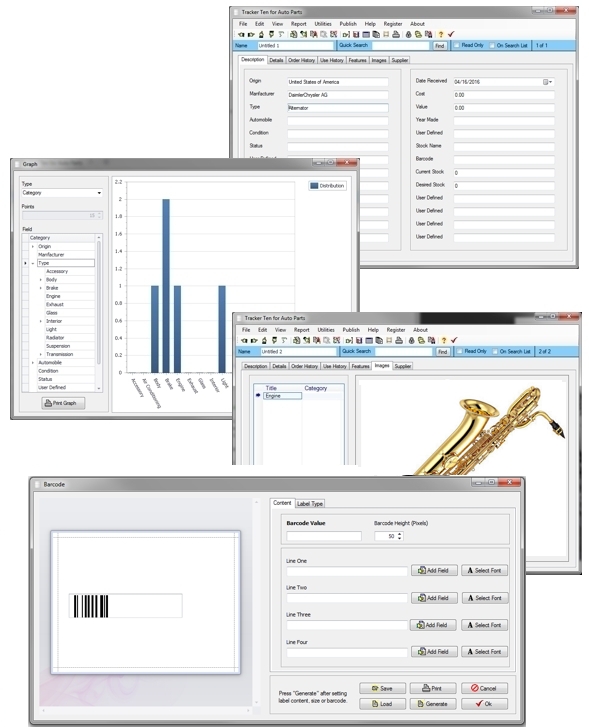

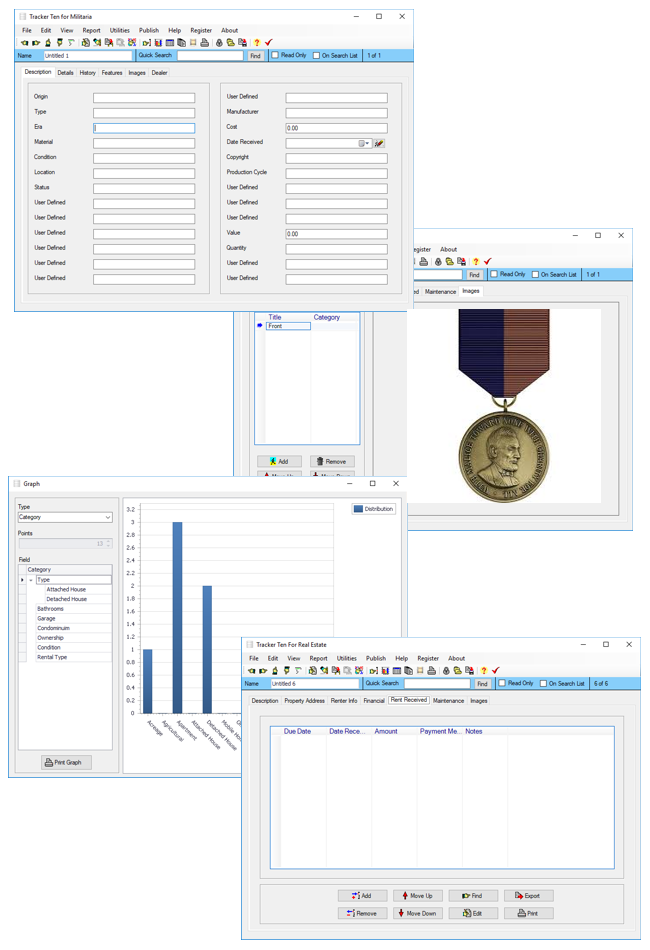

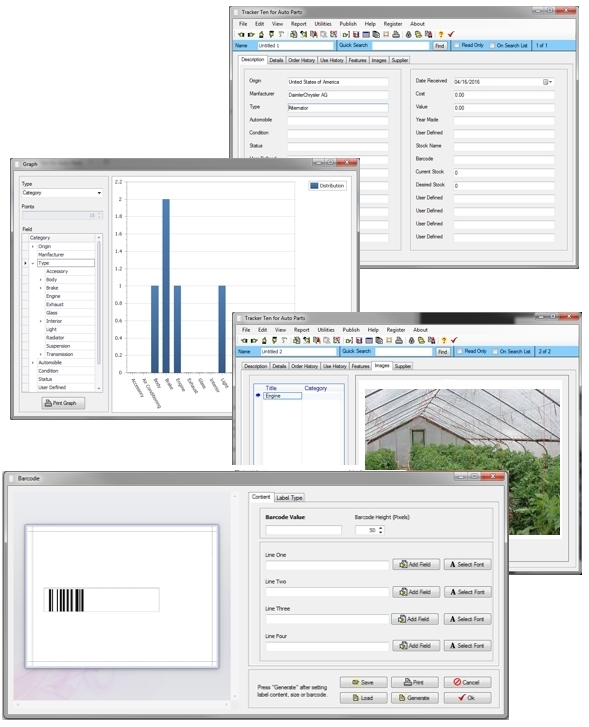

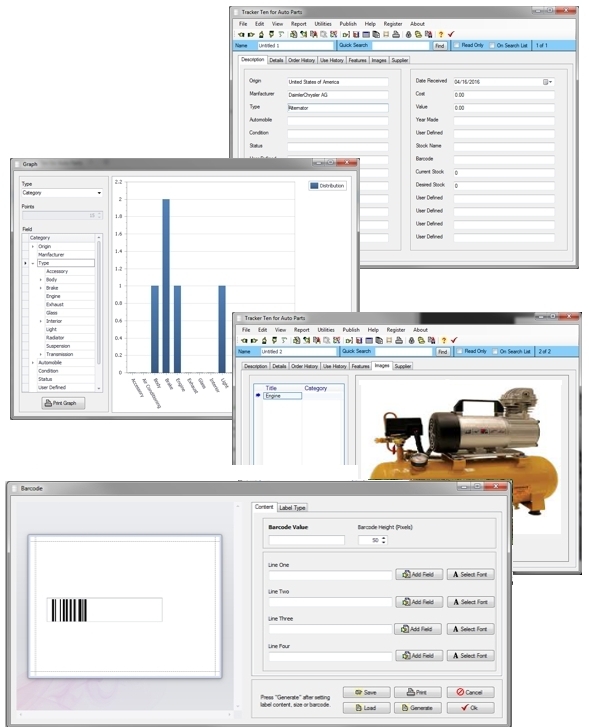

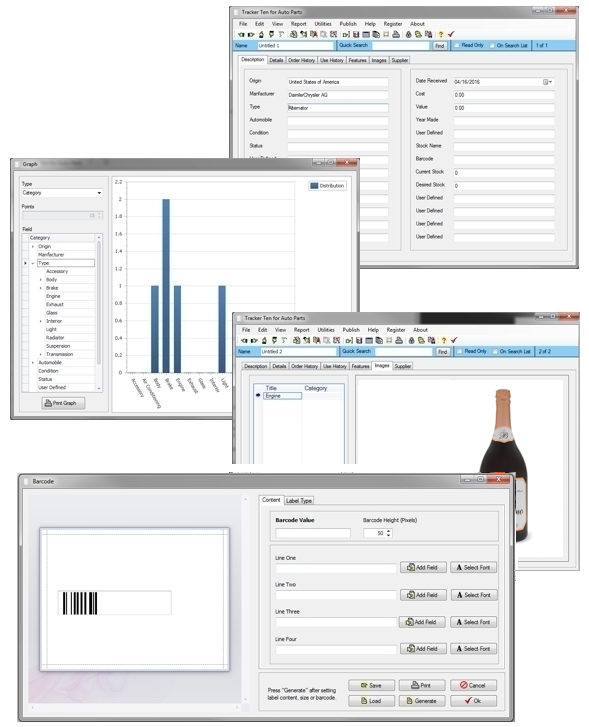

Tracker Ten for Machinery is a modern, Windows-based software solution designed to help businesses and service organizations efficiently track and manage machinery of all types. For many companies, machinery represents a significant investment and plays a critical role in daily operations. Whether the equipment is used in manufacturing, construction, transportation, agriculture, or maintenance services, keeping accurate records is essential for safety, cost control, and operational reliability. Tracker Ten for Machinery provides a centralized, customizable system that transforms machinery tracking from a reactive task into a proactive management process.

One of the most important functions of Tracker Ten for Machinery is its ability to maintain detailed machinery records. Each piece of equipment can be assigned its own record containing identifying information such as machine type, model, serial number, location, and operational role. This ensures that every asset is clearly documented and easily distinguishable, even in environments with large fleets or multiple sites. Centralized records eliminate the confusion that can arise from paper logs or disconnected spreadsheets and provide a single source of truth for equipment information.

Service history and cost tracking are core features of the software and among its greatest benefits. For each machine, users can record service events such as routine maintenance, repairs, part replacements, and inspections. These entries can include dates, descriptions of work performed, service providers, downtime, and associated costs. Over time, this builds a complete maintenance history that helps businesses understand the true cost of owning and operating each piece of machinery. With this information readily available, managers can identify recurring issues, evaluate maintenance effectiveness, and make informed decisions about repair versus replacement.

Cost tracking adds financial clarity that is especially valuable for budgeting and asset management. By recording service and maintenance expenses, Tracker Ten for Machinery allows businesses to see which machines are the most expensive to maintain. This insight supports long-term planning and helps justify capital investments in newer or more reliable equipment. For service-based businesses that bill clients for equipment use or maintenance, detailed cost records also improve accuracy and transparency.

Safety check tracking is another critical feature, particularly in industries where compliance and worker safety are top priorities. Tracker Ten for Machinery enables users to document safety inspections, certifications, and compliance checks for each machine. This ensures that required inspections are completed on time and that records are available for audits or regulatory reviews. By tracking safety checks systematically, businesses reduce the risk of accidents, fines, and operational disruptions. Clear safety records also demonstrate a commitment to best practices and employee well-being.

The ability to generate reports showing upcoming service dates and safety checks is a powerful tool for proactive management. Instead of reacting to breakdowns or missed inspections, businesses can plan maintenance and inspections in advance. Tracker Ten for Machinery makes it easy to identify which machines are due for service or safety reviews, helping managers schedule work efficiently and minimize downtime. This forward-looking approach improves equipment reliability and keeps operations running smoothly.

Image and PDF storage further enhance the software’s usefulness by allowing important documents to be stored directly with machinery records. Users can attach photos of equipment, serial plates, or damage, as well as PDF documents such as manuals, warranties, inspection certificates, and service invoices. Having these materials readily accessible saves time and reduces reliance on physical filing systems. When technicians or managers need information quickly, everything is available in one place.

Customizable fields are a key strength of Tracker Ten for Machinery, making it adaptable to a wide range of applications. Different industries and organizations track different types of information, and the software’s flexibility allows users to define fields that match their specific needs. For example, a construction company might track usage hours and job assignments, while a manufacturing facility might focus on production capacity and shift usage. This customization ensures that the software fits existing workflows rather than forcing changes to established processes.

The software’s easy searching capability supports fast access to information, even as machinery inventories grow. Users can quickly locate records by machine name, serial number, location, or other criteria. This is particularly valuable in large organizations where equipment is spread across multiple departments or sites. Fast search reduces downtime and improves responsiveness when issues arise.

Full color reporting adds clarity and professionalism to equipment documentation. Tracker Ten for Machinery allows users to generate visually clear reports that summarize machinery status, maintenance history, costs, and compliance information. These reports can be shared with management, auditors, or clients, supporting transparency and accountability. Full color formatting also makes it easier to highlight key information, such as overdue services or upcoming inspections.

From an operational perspective, Tracker Ten for Machinery helps businesses move from reactive maintenance to preventive and predictive strategies. With complete service histories and upcoming schedules visible at a glance, organizations can plan maintenance during low-impact periods and avoid unexpected failures. This reduces downtime, extends equipment life, and improves overall productivity.

For service organizations that manage machinery on behalf of clients, the software provides a structured way to track assets and deliver consistent service. Detailed records and reports support clear communication with clients and demonstrate professionalism. Clients benefit from better-maintained equipment and transparent documentation, while service providers benefit from improved efficiency and trust.

The software’s design for newer versions of Windows ensures compatibility with modern systems and supports reliable performance. Many businesses prefer desktop-based solutions that provide direct control over data and do not rely on constant internet connectivity. Tracker Ten for Machinery aligns well with these preferences, offering a robust local solution that still feels modern and user-friendly.

In addition to daily operational benefits, Tracker Ten for Machinery supports long-term strategic planning. Historical data on service costs, downtime, and safety issues can be analyzed to guide future investments and improvements. Managers can identify trends, such as increasing maintenance costs or recurring safety concerns, and take action before problems escalate.

In conclusion, Tracker Ten for Machinery is a comprehensive and flexible solution for tracking and managing machinery in a wide range of business environments. By centralizing machinery records, service histories, costs, safety checks, images, and documents, the software provides clear visibility and control over critical assets. Its customizable fields, easy searching, and full color reporting support both day-to-day operations and long-term decision-making. For businesses seeking to improve equipment reliability, control costs, and maintain high safety standards, Tracker Ten for Machinery offers a practical and effective tool for modern machinery management.

Looking for windows database software? Try Tracker Ten

- PREVIOUS Managing Personal Protective Equipment Thursday, November 28, 2024

- NextAll About Database Partitioning Sunday, November 17, 2024