Equipment

All About Barcode Scanners

Barcode scanning and barcode generation are foundational technologies in modern inventory management, logistics, retail operations, healthcare systems, and many other industries. Tasks that once required handwritten logs or manual data entry can now be completed in seconds with a quick scan. Many Tracker Ten applications support barcode scanners, enabling businesses and organizations to automate tracking processes with greater speed and accuracy. You can determine whether a specific version of Tracker Ten supports barcode scanning or barcode generation by reviewing its feature list. To truly understand the value of this technology, it helps to explore what barcodes are, how they function, and the different types of scanners used to read them.

Barcode Numbers Explained

Barcodes are visual representations of data, typically strings of numbers or alphanumeric characters, designed to be read by machines rather than humans. They are composed of vertical bars and spaces arranged in precise patterns. Each variation in width and spacing represents encoded information that computer hardware can quickly decode. The name "barcode" comes from these vertical bars, which together form a machine-readable language.

Barcodes appear everywhere in daily life. They are printed on retail products, shipping labels, library books, airline boarding passes, and official documents such as passports. Their usefulness extends well beyond retail. In healthcare environments, for example, barcode scanners are used to track patient wristbands, medications, laboratory samples, and medical records. This helps reduce errors, improve accountability, and enhance patient safety.

There are many different barcode formats, and distinguishing between them visually can be difficult. Common formats include EAN, Code 11, Code 39, Code 128, Interleaved 2 of 5, Industrial barcodes, and various extended formats. Some barcode types are numeric-only, meaning they can encode digits but not letters. Other formats support alphanumeric data and can represent the full ASCII character set, including letters, numbers, and symbols.

Among all barcode standards, Code 128 is one of the most widely used. It is compact, efficient, and highly reliable, making it easy for scanners to read accurately. Because of these advantages, Code 128 is often considered one of the best general-purpose barcode formats. Many barcode standards also include error-checking features such as check digits. A check digit is an automatically calculated value added to the barcode based on the encoded data. When the barcode is scanned, the system recalculates this value to confirm that the barcode was read correctly.

Fortunately, most end users do not need to understand barcode formats or the mathematics behind check digits. Modern barcode scanners are typically plug-and-play devices that can read many barcode formats automatically. As long as the barcode is clear and the scanner supports the format, scanning is fast and reliable.

Types of Barcode Scanners

Barcode scanners generally rely on one of two primary technologies: laser scanning or imaging-based scanning. Laser scanners project a beam of light across the barcode and measure how that light reflects back. Dark bars absorb light, while lighter spaces reflect it. By analyzing these reflections, the scanner determines the encoded data. This technology has been used for decades and remains common in retail checkout environments.

Imaging scanners, also known as linear or area imagers, work differently. They capture an image of the barcode and then use software algorithms to analyze the visual data. This approach is similar to how a digital camera functions. Imaging scanners are highly versatile because they can read barcodes from screens, handle damaged or poorly printed barcodes more effectively, and support two-dimensional codes such as QR codes.

QR codes and traditional barcodes are closely related. Both represent data visually, but QR codes are designed to store significantly more information in a compact square format. QR codes are easily scanned using smartphones and tablets, while traditional barcodes are optimized for specialized scanners commonly used in commercial and industrial environments.

Because barcodes are so widespread, centralized barcode databases and APIs now exist. These services allow software systems to take a scanned barcode value and look up associated product information such as name, manufacturer, and category. In many cases, the barcode represents a globally recognized identification number such as a GSIN. If barcodes are used only for internal purposes, such as tracking items within a warehouse or office, global registration may not be necessary. However, businesses that want their products recognized worldwide must obtain unique identifiers from organizations like GS1.

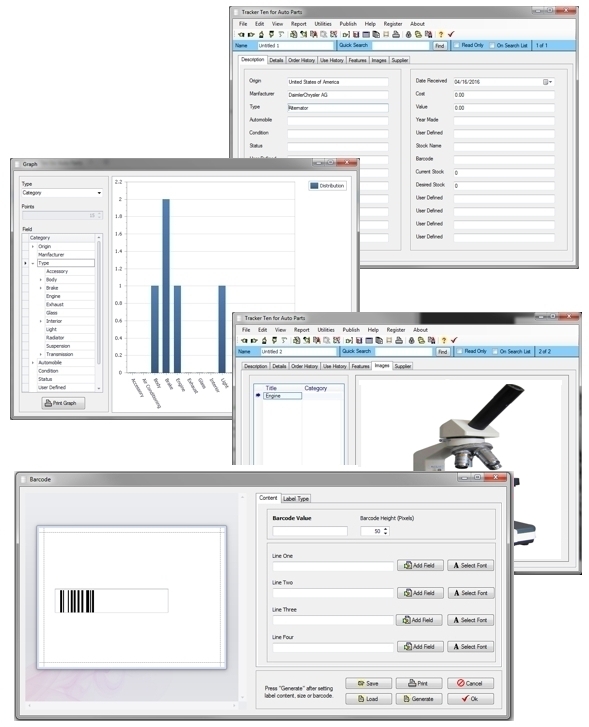

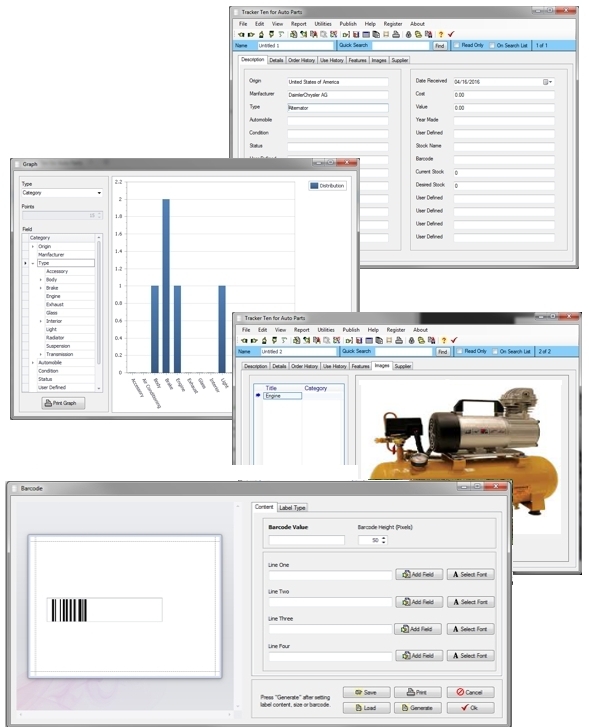

Obtaining GS1 numbers involves additional costs, and it may not always be worthwhile for smaller organizations. It is important to note that a GS1 barcode generator is not fundamentally different from a standard barcode generator. The difference lies in the registration and uniqueness of the underlying numbers. Tracker Ten software can generate GS1-compliant barcode images if you already have GS1 numbers and can also scan existing GS1 barcodes. For internal use, Tracker Ten can automatically generate unique barcodes at no additional cost.

Handheld, Fixed, and Wireless Scanners

Most barcode scanners are handheld devices, but fixed barcode scanners are also widely used. Fixed scanners are commonly found in grocery store checkout counters, where items are passed over an in-counter scanner. The primary advantage of fixed scanners is that they allow for hands-free operation and high-speed scanning. The main limitation is that items must be brought to the scanner, making these systems best suited for smaller products.

Fixed barcode scanners are manufactured by companies such as Honeywell, Datalogic, and Keyence and are often integrated into sophisticated point-of-sale systems. Handheld scanners, on the other hand, are produced by manufacturers like Symbol and Zebra. These scanners may be corded or wireless and are available in ruggedized designs for warehouses and retail stores, as well as lightweight models for office or home use.

Barcode scanners are available across a wide range of price points. Basic models can be very affordable, while advanced scanners with built-in displays, memory, and computing capabilities can cost thousands of dollars. High-end scanners often function as handheld computers or mini terminals. For most inventory and office applications, an inexpensive scanner is sufficient. However, environments that involve damaged, dirty, or poorly printed barcodes may benefit from more advanced scanning technology.

Connectivity and Integration

Most modern barcode scanners connect directly to a computer using a USB port and do not require special drivers. Even many wireless scanners include a base station that connects via USB. Older scanners may use serial or Ethernet connections, but these are becoming increasingly rare. Many scanners use a "keyboard wedge" interface, meaning they send data to the computer as if it were typed on a keyboard. As a result, the computer cannot distinguish between keyboard input and scanner input.

This simple interface makes barcode scanners easy to integrate with software systems. Tracker Ten software works with any USB barcode scanner that supports a keyboard wedge interface. Wireless scanners may transmit data in real time or store scanned barcodes in internal memory for later synchronization. Systems that rely on stored scans may require custom software integration. Tracker Ten can provide this custom programming when needed.

Using Barcodes to Track Incoming and Outgoing Stock

Barcodes are powerful tools for tracking inventory as it moves in and out of stock. By assigning a unique barcode to each item, organizations can quickly record transactions, reduce manual data entry errors, and maintain accurate, real-time inventory records. Tracker Ten for Inventory Control and Tracker Ten for Stock Rooms provide all-in-one solutions that make barcode-based inventory tracking accessible and affordable. For organizations with specialized needs, custom barcode scanning solutions are also available, ensuring that barcode technology can adapt to virtually any workflow.

Using Barcode To Track Incoming and Outgoing Stock

If you would like to use barcode scanners to help you keep track of your incoming and outgoing inventory, please have a look at our Tracker Ten for Inventory Control and Tracker Ten for Stock Rooms products. Our all-in-one systems will let you inexpensively unlock the power of barcodes. And if you need a custom barcode scanning solution, please feel free to contact us.

Looking for windows database software? Try Tracker Ten

- PREVIOUS Hardware Required for a Stand Alone Database System Monday, October 7, 2024

- NextStoring Geographic Information in a Database Thursday, September 26, 2024