Software

Dental Lab Equipment and Supply Tracking Database Software

Tracker Ten for Lab Equipment is a flexible, database-driven software tool that can be adapted to the specialized needs of a dental laboratory for tracking equipment, supplies, and operational workflows. Although originally designed for general laboratory environments, its robust feature set makes it an excellent foundation for managing the complex inventory demands of a dental lab—from precision instruments and equipment to consumable materials and maintenance records. By providing a centralized, searchable, and customizable system for recording detailed information about virtually every physical item in your lab, Tracker Ten can transform chaotic spreadsheets and manual logs into an organized and efficient asset-management ecosystem.

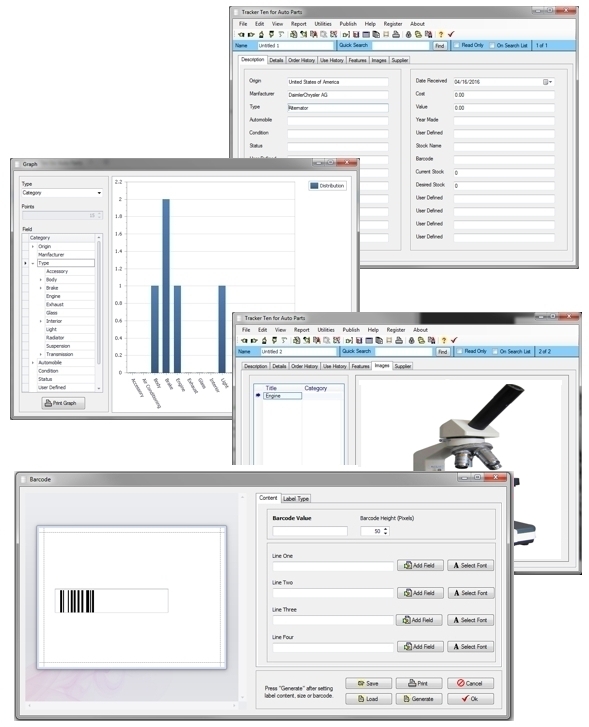

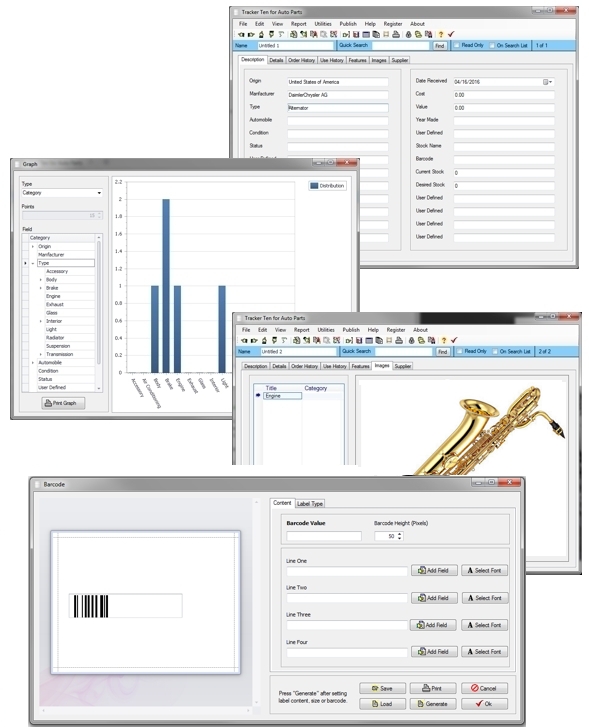

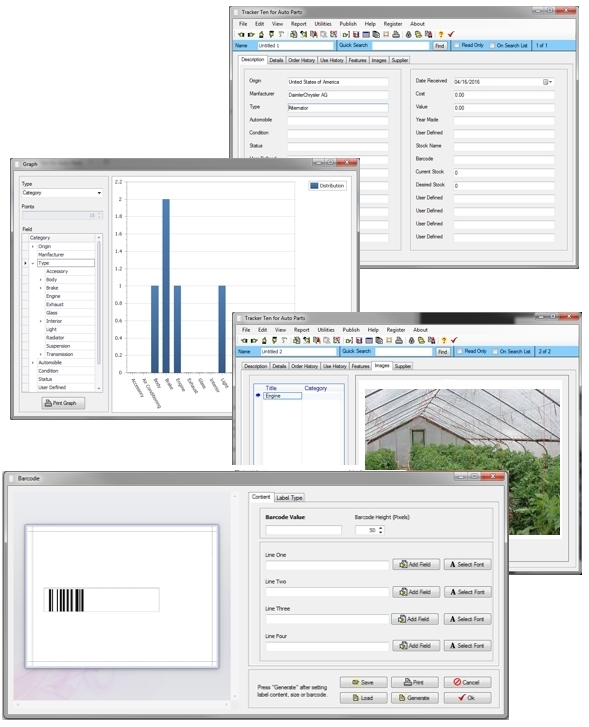

At the heart of Tracker Ten lies its ability to catalog comprehensive details about each piece of equipment and supply. In a dental lab, this capability means going far beyond simple lists of instruments. You can record manufacturer details, model numbers, serial numbers, warranty information, and build dates for critical equipment such as milling machines, ultrasonic cleaners, curing lights, articulators, and microscopes. Supplies like impression materials, bonding agents, burs, polishing compounds, and dental ceramics can be tracked not just for quantity but for supplier, lot number, expiration dates, and usage history. This level of detail creates a richer asset profile for every item under your lab’s control and supports both operational planning and compliance needs.

Click here to get a free demo of Tracker Ten for Lab Equipment.

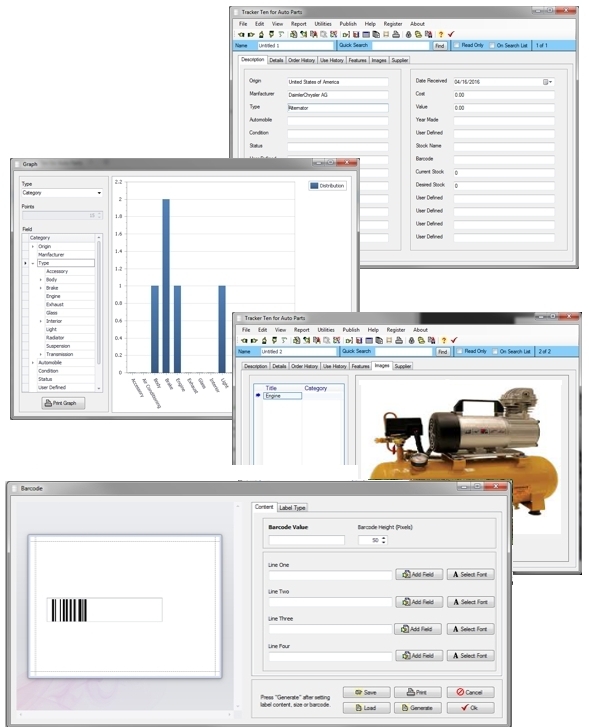

One of the most compelling reasons to use Tracker Ten in a dental lab is its support for barcode scanning and generation. Barcodes can be printed and affixed to instruments and supply bins, allowing staff to add or remove items from inventory with a simple scan instead of manual entry. This speeds up daily inventory checks and reduces the risk of human error—especially important in busy labs where dozens of dental prosthetics, devices, and consumables are used each day. Barcode tools also make it easier to perform regular stocktakes and identify low levels of critical supplies before they impact production schedules. By integrating barcodes into your workflow, you enhance accountability and get real-time visibility into inventory movements.

Tracker Ten’s reporting and data visualization features serve as powerful assets for a dental lab manager. The software can generate advanced reports showing inventory levels, usage trends, value summaries, and upcoming inspection or maintenance schedules. Graphs and charts can highlight patterns—such as which materials are being consumed most rapidly or which pieces of equipment require frequent service—which can inform purchasing decisions and budgeting conversations. For example, if you notice that a particular type of bur or ceramic block is consistently depleted ahead of schedule, you can adjust order quantities or negotiate better terms with suppliers to reduce cost and avoid stockouts.

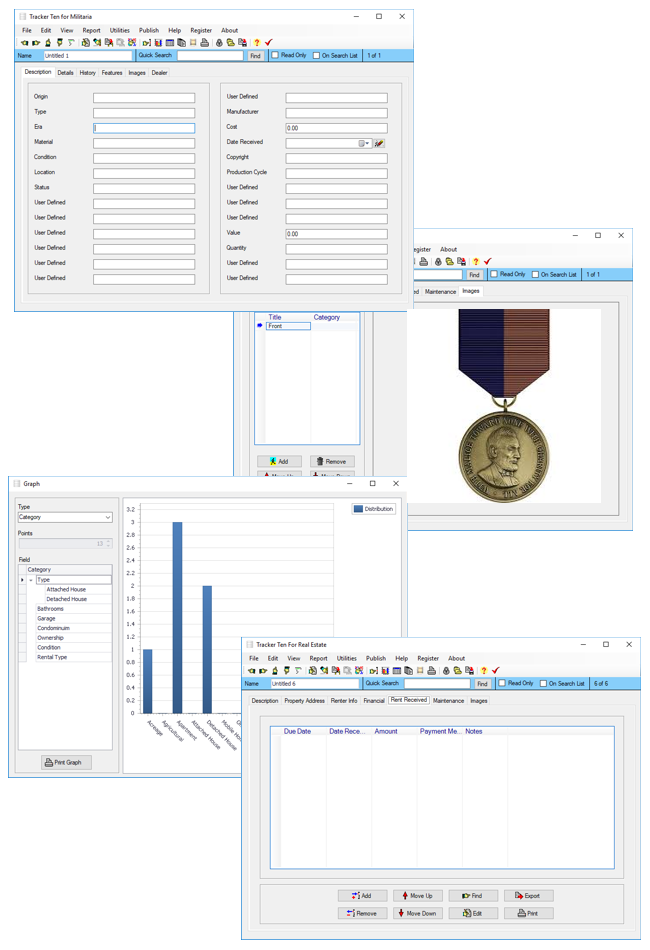

A critical part of inventory management in a dental lab is monitoring the lifecycle of equipment and supplies. Tracker Ten lets you record maintenance history and service costs, which is especially valuable for expensive equipment like CAD/CAM milling units and 3D printers. Every repair, calibration, or inspection can be logged, along with associated costs and dates. By doing this, you not only maintain a reliable maintenance record for compliance and warranty claims but also build a data set that reveals the long-term performance of your assets. This helps in determining when to retire or replace equipment before it fails at an inconvenient moment.

The software’s customizable fields and user-defined categories make it adaptable to the specific terminology and workflows of dental labs. Unlike generic inventory systems that might force you into rigid templates, Tracker Ten lets you tailor the database to reflect your unique naming conventions, categories (e.g., impression materials, restorative materials, orthodontic instruments), and tracking needs. This makes it easier for your team to use the system in a way that matches how they actually work, reducing resistance to adoption and improving data accuracy.

Supply cost tracking is another feature that has particular relevance in the dental lab setting. By recording not only the quantity of supplies on hand but also their cost and usage history, you gain clarity on how resources are being consumed. This cost visibility can feed directly into financial planning and pricing models, ensuring that your lab remains profitable while maintaining high standards of care. With supply cost data in hand, you can analyze which materials are driving up costs and explore alternatives or negotiate better supplier contracts based on documented usage patterns.

Location tracking within a dental lab can also be invaluable. Many labs operate with multiple workstations, equipment rooms, storage zones, and sterilization areas. Tracker Ten allows items to be tagged with precise locations, so you always know where an instrument or batch of materials is stored. This prevents time wasted searching for tools and reduces the chances of misplacing critical items during peak operational periods. The ability to locate instruments and supplies quickly is especially beneficial when deadlines are tight, such as when producing crowns, bridges, or aligners for patients on a schedule.

In addition to tracking physical items, Tracker Ten can support documentation management by linking to PDF product manuals and other electronic resources. For complex devices like autoclaves, curing units, or scanners, having quick access to manuals, safety sheets, and calibration documents through the inventory system can save time and enhance compliance. Centralizing these materials within the same system that tracks the equipment eliminates fragmentation and ensures that important documents are not lost in shared drives or email threads.

Perhaps one of the most underrated benefits of implementing a system like Tracker Ten is the improvement in audit readiness. Dental labs often face internal reviews, external quality assessments, and regulatory audits that require demonstrating control over instruments, materials, and processes. With a centralized database that logs everything from purchase date to maintenance history, you can produce audit reports on demand and demonstrate traceability for critical items. This capability builds confidence with clients, partners, and regulatory bodies.

Data export features further enhance the usefulness of Tracker Ten by allowing you to share inventory data with other applications or stakeholders. Exported data can be used for budgeting, integration with accounting software, or long-term archival. If your lab uses spreadsheets for financial planning or business analysis, exporting inventory data in a usable format streamlines collaboration and eliminates double data entry. This interoperability supports organizational workflows and ensures that inventory insights contribute to broader business decisions.

Although Tracker Ten is not designed exclusively for dental labs, its feature set is broad and deep enough to cover many of the core challenges these labs face around equipment and supply tracking. With the right configuration, it becomes a tailored tool that reflects the specific needs of your practice, from detailed instrument records to consumable supply tracking and lifecycle management.

Successful adoption of any inventory system depends on user buy-in and consistent data entry. In the context of dental labs, this means training staff to use Tracker Ten consistently—scanning barcodes, recording when materials are used, updating equipment status, and noting maintenance events. While this requires some cultural shift from manual methods to digital tracking, the long-term benefits in efficiency, accuracy, and cost control justify the effort.

In conclusion, Tracker Ten for Lab Equipment provides a robust foundation for dental lab inventory and equipment management. Its combination of detailed item records, barcode integration, customizable fields, reporting tools, and flexible data export options creates a comprehensive solution for tracking everything from high-value equipment to daily consumables. By adopting a structured system like Tracker Ten, dental labs can increase operational efficiency, reduce waste, maintain compliance, and make more informed decisions grounded in real data.

Looking for windows database software? Try Tracker Ten

- PREVIOUS Tracking Customers For Your Small Business Tuesday, November 12, 2024

- NextDatabases for Small Projects Sunday, November 3, 2024