Business

Inventory Management Best Practices

Inventory management is a critical function for any business that sells physical products. Proper inventory management ensures that the right products are available in the right quantities at the right time, helping businesses meet customer demand while minimizing costs. Poor inventory management can lead to stockouts, overstocking, lost sales, and wasted resources. Implementing best practices can dramatically improve efficiency, profitability, and customer satisfaction. Below, we explore key strategies for effective inventory management.

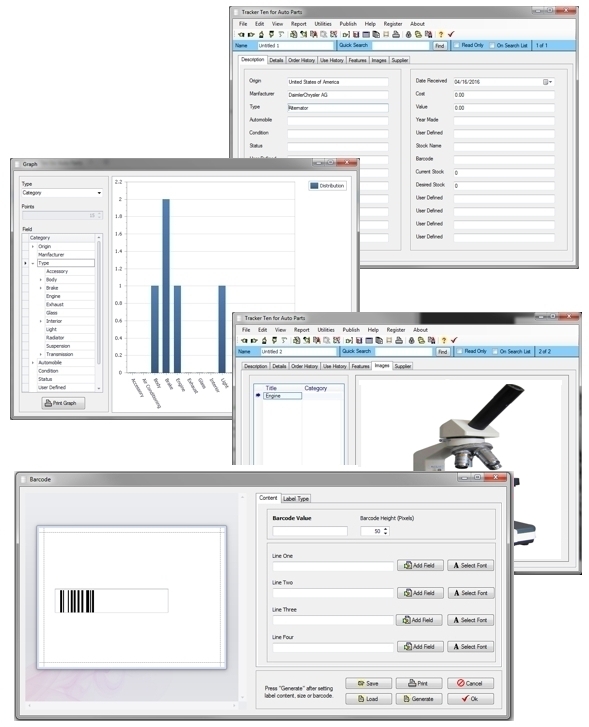

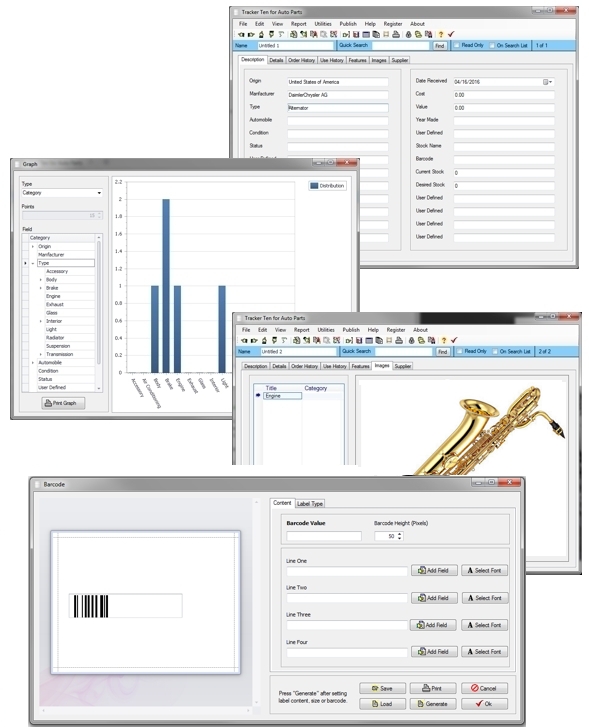

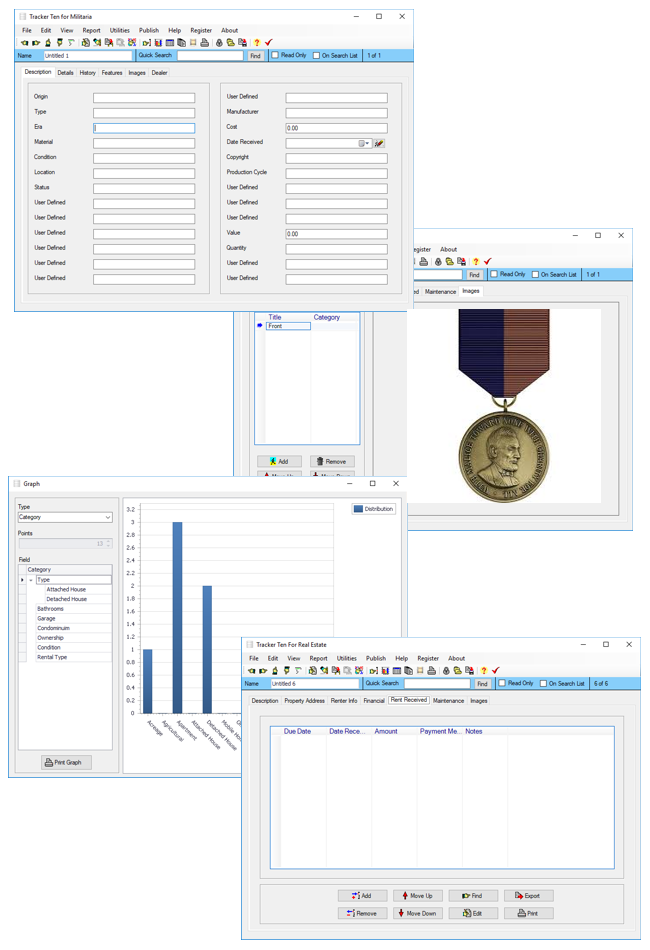

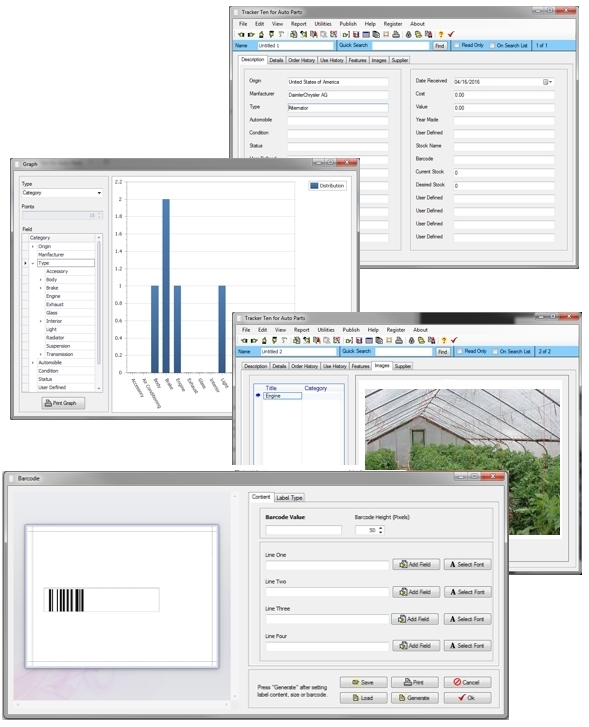

Use inventory management software: Modern inventory management software is a cornerstone of efficient operations. These systems track inventory levels, set reorder points, and generate analytical reports on sales trends, product performance, and inventory turnover. Many solutions integrate with point-of-sale systems, accounting software, and e-commerce platforms, providing a complete view of your stock in real-time.

Implement a first-in, first-out (FIFO) system: FIFO ensures that older stock is sold before newer inventory. This is particularly important for perishable goods, seasonal products, or items with expiration dates. FIFO reduces spoilage and obsolescence, ensuring that customers receive fresh products and minimizing losses.

Establish inventory reorder points: Reorder points indicate the minimum quantity of a product that should be on hand before a new order is placed. Setting reorder points based on historical sales data, lead times from suppliers, and seasonal demand ensures you maintain optimal stock levels without tying up excess capital.

Conduct regular physical inventory counts: Regular counts help identify discrepancies between recorded inventory levels and actual stock. Cycle counting, where small portions of inventory are counted on a rotating schedule, can minimize disruption while maintaining accuracy. Annual full physical counts can also provide a complete verification of stock levels.

Segment inventory based on sales velocity: Classifying inventory by sales velocity—fast-moving, slow-moving, or obsolete—helps prioritize restocking and liquidation decisions. Fast-moving items should be replenished frequently, while slow-moving items may require promotional strategies or discounts to reduce carrying costs.

Implement quality control measures: Proper handling and storage are essential for maintaining product quality. Temperature-sensitive items, fragile goods, and products with expiration dates require monitoring to prevent damage or spoilage. Implementing strict quality control protocols ensures your customers receive products in perfect condition.

Analyze sales trends and adjust inventory levels: Regularly review sales data to predict demand fluctuations and adjust inventory levels accordingly. Seasonal trends, promotional campaigns, and economic factors can affect demand, so proactive adjustments reduce the risk of stockouts or overstocking.

Optimize storage space: Efficient use of warehouse space minimizes costs and improves workflow. Use vertical storage, implement a bin system, or consider automated storage and retrieval systems. Organized storage reduces retrieval time and prevents misplaced inventory.

Maintain accurate records: Accurate inventory records are critical for effective decision-making. Ensure that all transactions, including receipts, shipments, returns, and adjustments, are promptly recorded in your inventory management system.

Monitor supplier performance: Supplier reliability affects your ability to maintain optimal stock levels. Track supplier delivery times, product quality, and responsiveness to issues. Establish strong relationships with reliable suppliers to reduce risk of stockouts and improve procurement efficiency.

Use a just-in-time (JIT) inventory system: JIT minimizes inventory holding costs by receiving goods only when needed for production or sale. This reduces storage requirements, lowers risk of obsolescence, and ensures cash flow is not tied up in excess inventory. However, JIT requires strong supplier coordination to prevent stockouts.

Set safety stock levels: Safety stock is extra inventory held to buffer against unexpected demand spikes or supply delays. Calculating safety stock requires analysis of historical sales variability, supplier lead times, and acceptable service levels. Properly maintained safety stock prevents lost sales without incurring unnecessary carrying costs.

Implement a stock rotation system: Stock rotation ensures that older inventory is sold first. Techniques like FIFO or LIFO (last-in, first-out, for specific scenarios) help reduce waste and maintain product freshness. Rotate stock strategically to avoid over-aging inventory and customer complaints.

Use barcoding or RFID technology: Automated tracking through barcodes or RFID improves accuracy, reduces errors, and provides real-time inventory visibility. Barcode scanners and RFID readers help track movements, reduce manual entry, and facilitate faster cycle counts.

Train employees on proper inventory procedures: Human error is a leading cause of inventory discrepancies. Train staff on inventory software, proper handling techniques, storage best practices, and how to conduct counts. Continuous training ensures efficiency and minimizes costly mistakes.

Conduct regular inventory audits: Audits identify discrepancies, errors, and potential fraud. Periodic auditing, whether full physical counts or cycle counting, ensures that inventory records match actual stock levels and enhances accountability.

Implementing these best practices leads to improved inventory accuracy, reduced costs, and better alignment between stock levels and customer demand. Businesses that actively manage inventory are better equipped to respond to market changes and improve overall operational efficiency.

Inventory Management Equipment

Managing inventory effectively requires the right equipment and tools. Using appropriate technology and machinery ensures accuracy, speeds up workflow, and reduces human error. Common inventory management equipment includes:

Barcode scanners: Quickly and accurately read product barcodes to track inventory movements, sales, and stock levels. Handheld or fixed scanners improve accuracy compared to manual entry.

RFID readers: Track inventory in real-time using RFID tags on products or pallets. RFID enables high-volume, contactless scanning, providing granular data for inventory management.

Mobile devices: Smartphones, tablets, or handheld computers allow employees to access inventory management systems from anywhere in the warehouse, perform counts, and update stock levels on the go.

Inventory management software: Software systems automate tracking, reporting, and auditing of inventory. Advanced platforms integrate with accounting, POS, and ERP systems for full operational oversight.

Pallet jacks and forklifts: Move large quantities of inventory efficiently within storage facilities, reducing labor costs and improving speed of stock handling.

Storage and shelving equipment: Pallet racks, shelving units, and storage bins optimize warehouse layout and improve accessibility, ensuring products are stored safely and systematically.

Scales: Weigh inventory for accuracy in stock counts and order reconciliation. Critical for bulk products or items sold by weight.

Using a combination of software, hardware, and organizational equipment ensures efficient inventory management, reduces errors, and improves operational workflows.

Inventory Management Pitfalls

Even with the best systems, businesses can face pitfalls that undermine inventory management effectiveness. Recognizing and addressing these pitfalls is crucial for maintaining accurate stock and reducing costs.

Overstocking or understocking: Overstocking ties up capital and increases storage costs, while understocking leads to lost sales and dissatisfied customers. Balancing inventory with demand is essential.

Poor inventory visibility: Inaccurate or incomplete records can lead to mistakes in replenishment, misplaced stock, and operational inefficiency. Maintaining accurate, real-time records is essential.

Lack of forecasting: Failing to forecast demand can result in overstocking slow-moving items or stockouts during peak periods. Analyzing historical sales, seasonal trends, and market conditions is necessary for proper forecasting.

Inefficient storage and handling: Poor storage layouts, inadequate equipment, or improper handling can lead to product damage, spoilage, or safety hazards. Optimize layout and train staff on proper procedures.

Poor supplier management: Unreliable suppliers can cause delays, product quality issues, and higher costs. Monitor supplier performance and maintain strong relationships for consistent inventory flow.

Failure to audit inventory: Skipping regular audits increases the likelihood of discrepancies, theft, or mismanagement. Scheduled audits ensure records match actual stock and highlight operational issues.

Inadequate employee training: Improperly trained staff can make errors in stock handling, counting, and recording. Continuous training ensures efficiency and reduces mistakes.

Avoiding these pitfalls ensures that inventory levels remain accurate, operations are efficient, and customers receive the products they need.

Inventory Management Software

Effective inventory management requires robust software solutions. Modern inventory software offers:

- Real-time stock tracking and visibility

- Automated reordering and alerts

- Integration with POS, accounting, and e-commerce platforms

- Advanced reporting for sales, demand trends, and inventory turnover

- Support for barcoding, RFID, and mobile device scanning

- Audit trails and security features to prevent errors and theft

- Forecasting tools based on historical data and market trends

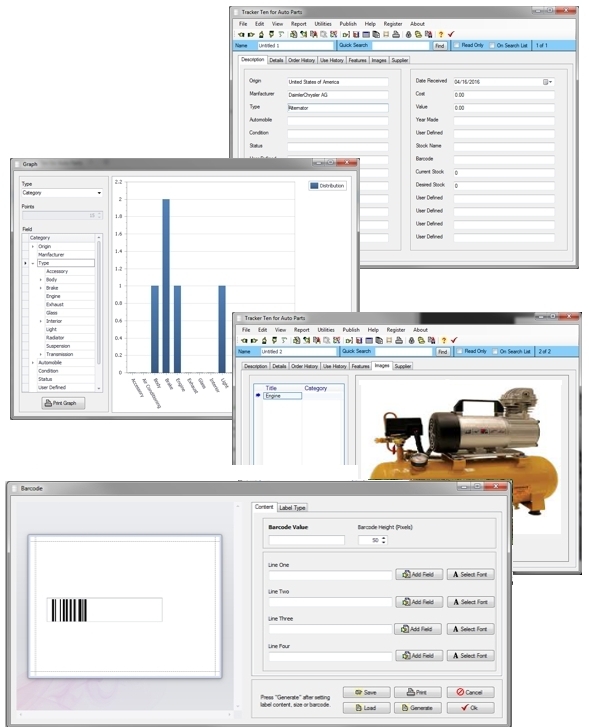

Using specialized inventory management software like Tracker Ten for Inventory Control can help businesses maintain accurate records, optimize stock levels, and improve overall efficiency. The software allows businesses to track inventory movement, monitor reorder points, set safety stock levels, and generate detailed reports to support decision-making and strategic planning.

Conclusion

Inventory management is a complex but critical aspect of any business that sells physical goods. By following best practices, using appropriate equipment, avoiding common pitfalls, and leveraging modern inventory management software, businesses can ensure that the right products are available at the right time. This improves operational efficiency, reduces costs, and enhances customer satisfaction. Implementing a structured and strategic approach to inventory management is an investment in the long-term success of your business.

Looking for windows database software? Try Tracker Ten

- PREVIOUS Cleaning Data Saturday, May 11, 2024

- NextDatabase Concurrency Saturday, May 11, 2024