Database

Keeping Track of Equipment Inspections

Regularly inspecting your equipment is crucial for keeping all facets of your operation running at peak efficiency. Whether you operate a small business, a medium-sized construction company, or a large factory, consistent equipment inspections are essential. From a single forklift or manlift to multiple cranes, trucks, or industrial vehicles, inspections ensure operational reliability and workplace safety.

Proper inspections allow you to perform preventive maintenance, replace worn-out items in advance, and reduce workplace hazards. Regular inspections help minimize downtime, increase operational efficiency, and create a safer work environment. Safe operations improve employee morale, reduce liability, and maintain your company’s reputation. Additionally, many jurisdictions legally require regular inspections to maintain compliance with safety regulations. Noncompliance can result in fines, forced downtime, and reputational damage.

Inspections are necessary across various industries, including warehouse equipment, medical equipment, manufacturing machinery, HVAC systems, farm equipment, and industrial vehicles. For organizations with a large inventory, manual tracking of inspections may be impractical, making dedicated inspection software an invaluable tool for managing compliance and operational efficiency.

Inspection Scheduling

Inspections may be scheduled at fixed intervals (daily, weekly, monthly, or annually) or based on usage (hours of operation, mileage, or cycles). Some inspections may also be random or spot checks to ensure equipment remains reliable under all conditions. Items with high wear potential, such as tires, belts, gears, windshields, or brakes, require particular attention.

Beyond visual wear, equipment calibration and functionality must be verified. Manufacturing equipment requires precise calibration to ensure product quality, and even non-moving devices like electronic sensors should be regularly inspected. Minor deviations can escalate into costly operational issues. In environments where hygiene is critical, such as dental offices or food services, cleanliness checks are equally important. Though inspections may be time-consuming, they prevent major disruptions, costly repairs, and safety incidents.

Types of Equipment Inspections

Equipment inspections range from simple visual checks to complex functional tests. Visual inspections identify signs of deterioration or damage, while functional inspections may involve diagnostics, calibration, or specialized tools. As equipment ages, inspection frequency may need to increase to maintain operational integrity. Some examples include:

Visual inspections: Check for cracks, rust, frayed cables, leaks, loose connections, and worn components.

Functional inspections: Test equipment operations under normal and extreme conditions to ensure proper performance.

Calibration checks: Confirm equipment measures accurately within factory specifications.

Hygiene inspections: Ensure cleanliness standards are maintained for medical, food, or lab equipment.

Safety inspections: Verify that safety mechanisms, emergency stops, and protective devices are functional.

Inspection Benefits

Regular inspections provide multiple benefits that directly impact your operational efficiency, safety, and financial outcomes. Some of these benefits include:

Reduced repair costs: Early detection of issues allows minor repairs to be addressed before major failures occur.

Improved safety: Identifying hazards prevents workplace injuries and enhances employee morale.

Regulatory compliance: Maintaining inspection records ensures compliance with laws, regulations, and industry standards.

Lower insurance premiums: Reduced risk of accidents and equipment failure may lower workers' compensation and liability insurance costs.

Operational efficiency: Minimizing downtime ensures equipment is available when needed, improving productivity.

Reputation management: Demonstrating consistent maintenance practices builds trust with clients and stakeholders.

Inspection Checklists

Creating a detailed inspection checklist ensures that no step is overlooked during equipment inspections. Checklists should combine manufacturer recommendations, regulatory guidelines, and experienced staff input. Key considerations include:

Checklist structure: Divide items into manageable categories to simplify inspections, e.g., mechanical, electrical, calibration, and safety checks.

Corrective actions: Include predefined corrective steps for common issues to streamline repairs and minimize downtime.

Regulatory alignment: Ensure checklists comply with OSHA, FDA, ISO, or local industry regulations.

Regular updates: Review and update checklists to incorporate new standards, equipment updates, or lessons learned.

If creating a checklist in-house is impractical, professional inspection agencies or OEM inspectors can provide certified checklists and perform inspections. Certified inspectors are familiar with regulations, industry standards, and critical equipment functions, ensuring reliable inspections.

Inspection Supplies and Equipment

Proper inspections require the right tools and supplies. While some inspections are purely visual, many require specialized instruments to detect underlying problems. Common inspection tools include:

- Flashlights and mirrors for visual access in tight areas

- Infrared thermometers for detecting heat anomalies

- Moisture detectors to identify leaks or condensation

- Multimeters or circuit testers for electrical components

- Calipers, micrometers, and measuring tools for precise measurements

- Diagnostic software for medical and electronic equipment

- Safety gear such as gloves, goggles, and protective clothing

Maintaining a well-stocked inspection kit ensures inspections are thorough and consistent. Keeping an inventory of your tools also allows you to quickly acquire replacements or additional items as needed.

Inspection Records

Documenting inspections is critical for compliance, liability reduction, and operational insight. Detailed inspection records provide evidence of proactive maintenance, demonstrate regulatory adherence, and support insurance claims in the event of accidents or equipment failures. Key practices include:

- Record the date, inspector, and findings for each inspection

- Document corrective actions taken

- Maintain historical records for trend analysis

- Integrate records with maintenance and asset management systems

- Ensure digital backups to prevent data loss

Inspection Software

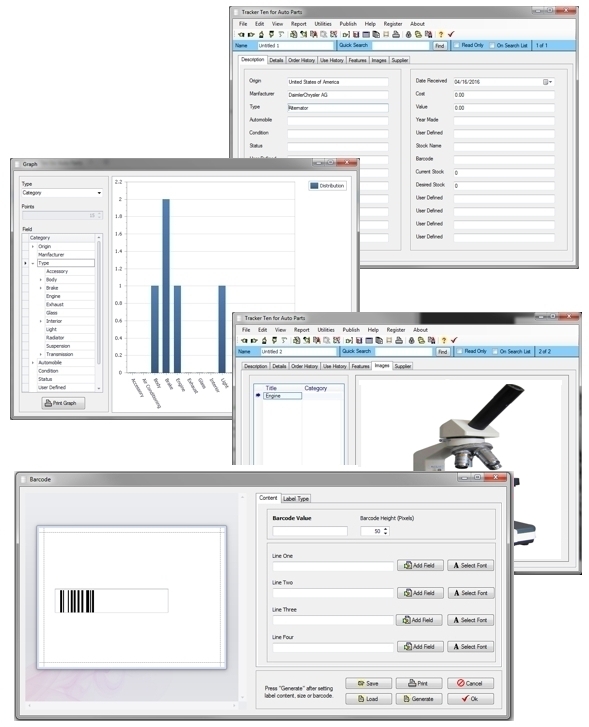

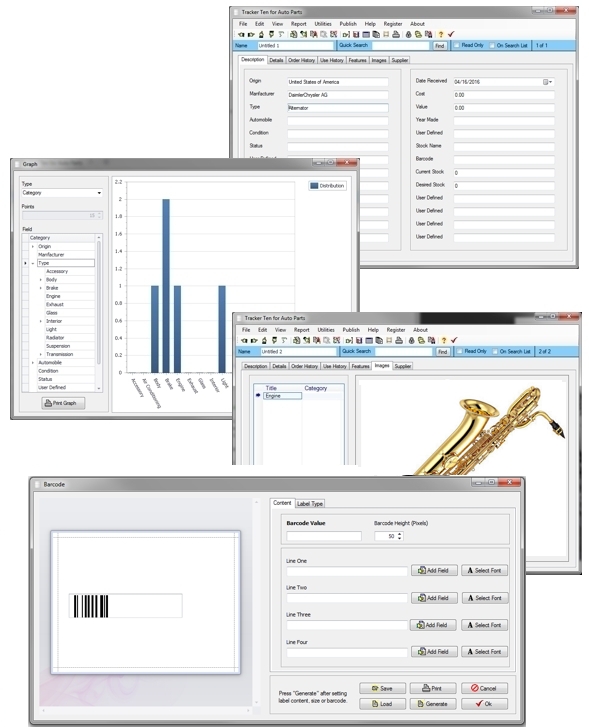

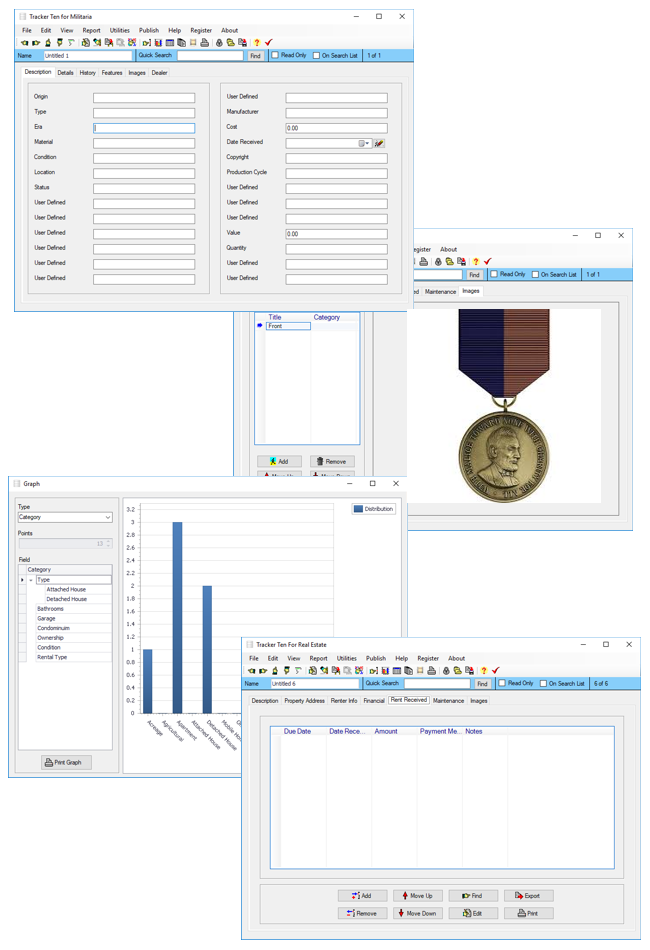

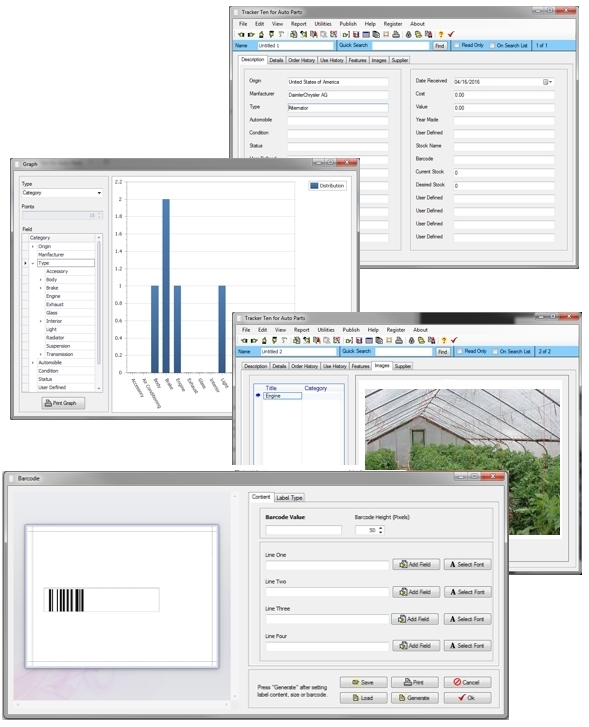

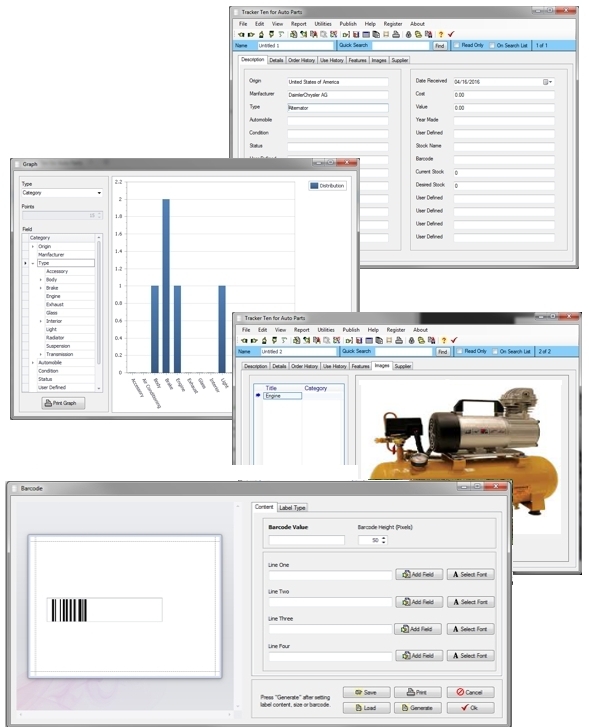

Manual tracking of inspections can be inefficient, particularly in organizations with large equipment inventories. Inspection software provides automated scheduling, reminders, documentation, and reporting. Our software solutions include:

- Tracker Ten for Equipment: For heavy equipment inspections, tracking schedules, results, and compliance.

- Tracker Ten for Medical Equipment: For hospitals, clinics, and dental offices to track device inspections and maintenance.

- Tracker Ten for Machinery: For factories, manufacturing plants, and industrial machinery inspection tracking.

Inspection software enhances efficiency by sending reminders, recording inspection dates, tracking responsible personnel, and storing historical records. By implementing such systems, organizations reduce human error, ensure compliance, and streamline preventive maintenance programs.

Best Practices for Effective Equipment Inspections

To maximize the benefits of inspections, organizations should adopt best practices tailored to their operational context. Recommended best practices include:

- Establish standardized procedures for all equipment types

- Train staff regularly on inspection protocols and equipment handling

- Use checklists tailored to specific equipment models

- Schedule inspections based on usage, environmental conditions, and manufacturer guidance

- Keep inspection logs centralized and easily accessible

- Use predictive analytics to anticipate maintenance needs

- Review and update procedures based on incident reports and evolving regulations

- Encourage staff feedback to improve inspection effectiveness

- Audit inspection processes periodically to ensure compliance and consistency

By following these best practices, organizations can maintain operational efficiency, prevent costly breakdowns, ensure safety, and maintain regulatory compliance.

Conclusion

Keeping track of equipment inspections is essential for operational efficiency, safety, and compliance across industries. From visual checks to detailed functional tests, inspections prevent downtime, reduce repair costs, protect employees, and ensure regulatory adherence. Utilizing checklists, proper tools, recordkeeping, and inspection software enhances effectiveness, efficiency, and reliability.

By integrating a structured inspection program and leveraging modern software solutions like Tracker Ten, organizations of all sizes can maintain equipment in optimal condition, ensure employee safety, and protect their investment in operational assets.

Looking for windows database software? Try Tracker Ten

- PREVIOUS Database Automation Tips and Tricks Sunday, July 27, 2025

- NextMobile Vs Desktop Databases Thursday, July 17, 2025