Database

Stockroom Inventory

Stockroom inventory refers to the collection of goods or products stored in a designated space or room for future use or sale. This inventory can include a wide range of items, such as raw materials, finished products, packaging supplies, office consumables, and more. Properly managing stockroom inventory is essential for businesses to maintain operational efficiency, ensure product availability, and minimize costs associated with overstocking or stockouts.

Efficient stockroom inventory management involves tracking the quantity of items, monitoring turnover rates, identifying slow-moving products, and ensuring timely replenishment. Organizations that fail to manage stockroom inventory effectively often face issues such as lost sales, wasted storage space, and increased holding costs. Conversely, a well-organized stockroom can streamline operations, reduce waste, improve profitability, and support a smooth supply chain.

Many modern businesses employ inventory management software to automate stockroom operations. Such systems help track inventory levels in real-time, generate reports on usage trends, predict future demand, and optimize purchasing decisions. Whether managing a small retail shop or a large warehouse, inventory software provides critical insights that enable managers to make informed decisions and respond quickly to changes in demand.

Proper stockroom inventory management also supports regulatory compliance, quality control, and efficient workforce management. By implementing standardized procedures, maintaining accurate records, and integrating technology, businesses can ensure their stockroom operations are optimized for both performance and cost-efficiency.

Stockroom Inventory Equipment

Stockroom inventory equipment refers to the tools, machinery, and devices used to manage and organize inventory efficiently. The right equipment can increase productivity, improve inventory accuracy, and reduce employee fatigue and errors. Common stockroom inventory equipment includes:

Shelving and racking systems: Shelves and racks provide organized storage for inventory items. Adjustable and modular systems allow businesses to customize storage based on product size and weight, improving space utilization.

Pallet jacks and forklifts: Essential for moving heavy items or pallets within the stockroom or warehouse, these devices reduce the risk of injury and speed up stock handling.

Barcode scanners and inventory management software: These technologies automate tracking, reduce manual errors, and provide instant access to stock information, enabling businesses to monitor levels, reorder efficiently, and generate reports.

Packing and shipping equipment: Items such as boxes, packing tape, bubble wrap, labeling machines, and postage meters ensure that products are safely prepared for shipment.

Safety equipment: Safety is paramount in stockrooms. Items like hard hats, steel-toed boots, gloves, and safety vests protect staff while handling heavy or hazardous materials.

Investing in the right stockroom equipment enhances operational efficiency, improves employee safety, and ensures accurate inventory management. Businesses that adopt modern equipment often experience faster order fulfillment, better space utilization, and reduced operational costs.

Stockroom Inventory and Supply Chain Management

Stockroom inventory management and supply chain management are deeply interconnected. Supply chain management involves coordinating the flow of goods from suppliers to end customers, encompassing procurement, production, distribution, and delivery. Effective stockroom inventory management ensures that inventory within a facility is available when needed, minimizing disruptions in the supply chain.

Proper inventory management allows businesses to maintain the right balance between overstock and stockouts. Overstocking can tie up capital, increase storage costs, and lead to product obsolescence. Stockouts, on the other hand, can result in lost sales, dissatisfied customers, and missed business opportunities. Inventory management tools such as barcode scanners, automated replenishment systems, and analytics software can help businesses monitor stock levels in real-time and optimize inventory decisions.

Additionally, stockroom inventory management is critical for supplier relationships. Businesses must coordinate ordering schedules, negotiate pricing, and manage lead times effectively to ensure smooth operations. By maintaining accurate inventory records and collaborating with suppliers, companies can reduce procurement costs, avoid delays, and enhance overall supply chain performance.

Efficient stockroom management also supports demand forecasting. Advanced software can analyze historical sales data, seasonal trends, and market conditions to predict future demand. This enables businesses to stock appropriate quantities, prevent shortages, and capitalize on market opportunities. Overall, integrating stockroom inventory management into the broader supply chain strategy is essential for operational success, customer satisfaction, and profitability.

Stockroom Staff

Stockroom staff are the backbone of inventory operations, responsible for managing, organizing, and maintaining inventory. The roles and responsibilities of stockroom personnel vary depending on the size of the facility and the complexity of operations. Key stockroom roles include:

Stockroom Manager: Oversees the entire stockroom operation, ensuring proper inventory levels, efficient workflows, and compliance with safety standards.

Stockroom Supervisor: Monitors day-to-day operations, supervises staff, and ensures procedures are followed for receiving, storing, and dispatching goods.

Stockroom Clerk: Responsible for recording and updating inventory data in management systems, conducting audits, and maintaining stock accuracy.

Stockroom Associate: Handles daily stockroom tasks such as receiving, organizing, picking, and preparing inventory for shipment.

Shipping and Receiving Clerk: Manages incoming and outgoing shipments, processes purchase orders, and coordinates with carriers to ensure timely delivery.

Stockroom staff play a critical role in ensuring inventory accuracy, preventing stock discrepancies, and maintaining smooth operations. Training, clear procedures, and the right tools are essential for maximizing staff efficiency and minimizing errors.

Stockroom Goods Expiration

Goods expiration is a crucial aspect of stockroom management, especially for perishable or time-sensitive products such as food, pharmaceuticals, and cosmetics. Expired products can pose health risks and damage a company’s reputation, making proper expiration management essential.

Businesses can manage goods expiration by implementing the following best practices:

Track expiration dates: Maintain a system for monitoring product shelf life. Inventory software can automate reminders and alerts for items nearing expiration.

Rotate inventory: Apply a first-in, first-out (FIFO) system to ensure older stock is sold or used first, minimizing the risk of expiration.

Regular inspection: Conduct routine checks to identify and remove expired items promptly. Frequency of inspections may vary depending on product type and turnover rate.

Proper disposal: Follow local regulations for disposing of expired goods, which may include recycling, composting, or hazardous waste procedures.

Effective expiration management reduces waste, protects consumers, and enhances inventory turnover. Businesses that adopt systematic approaches to managing shelf life gain better control over stock quality and profitability.

Stockroom Cold Storage

Cold storage is essential for managing temperature-sensitive products, including food, beverages, pharmaceuticals, and other perishable items. Cold storage facilities maintain specific temperature ranges using specialized equipment such as walk-in refrigerators, freezers, and climate-controlled rooms.

Key considerations for cold storage management include:

Temperature control: Maintain precise temperature levels to preserve product quality and prevent spoilage.

Inventory rotation: Apply FIFO principles to ensure older stock is utilized or sold first, reducing the risk of waste.

Monitoring and maintenance: Regularly check refrigeration equipment and monitor temperature and humidity to prevent product degradation.

Safety and compliance: Train staff in handling cold storage products safely and adhere to health regulations.

Cold storage stockroom management requires specialized skills, proper equipment, and diligent oversight. Implementing robust systems ensures product safety, reduces spoilage, and enhances operational efficiency.

Stockrooms vs Warehouses

While both stockrooms and warehouses store goods, there are significant differences. Stockrooms are smaller facilities often found in retail stores or small businesses, designed for immediate inventory needs. Warehouses are larger facilities used by manufacturers, distributors, and wholesalers to store large quantities of goods for long-term use or distribution.

Key distinctions include:

Size and capacity: Stockrooms are smaller, while warehouses handle large-scale inventory.

Inventory complexity: Stockrooms manage limited SKUs and require simpler systems, whereas warehouses require complex inventory management and tracking for thousands of items.

Staffing: Stockrooms may be managed by a few individuals, while warehouses need larger teams and specialized roles.

Equipment: Warehouses often use forklifts, conveyor belts, and pallet racks, while stockrooms rely on smaller-scale shelving and carts.

Understanding the differences allows businesses to design the appropriate inventory management systems, optimize space, and ensure efficient stock handling.

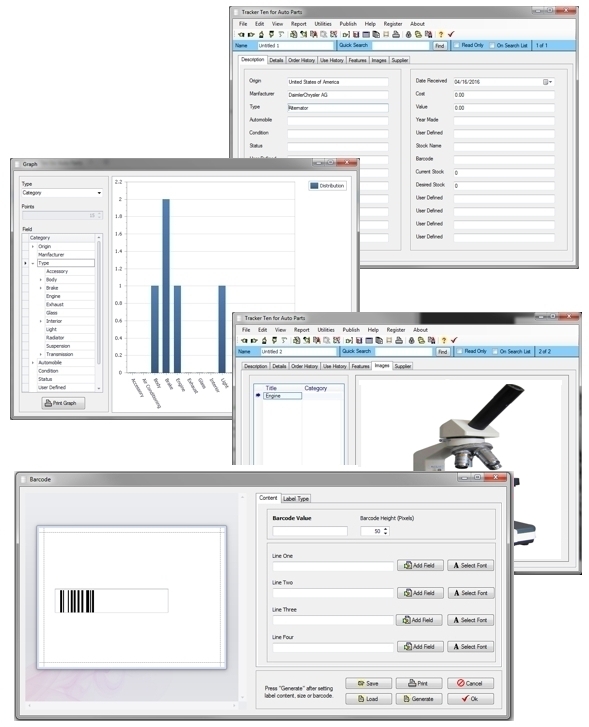

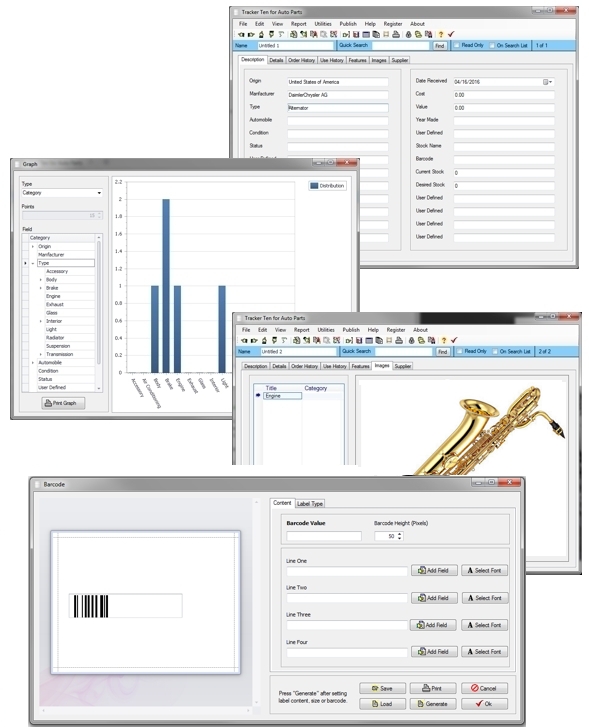

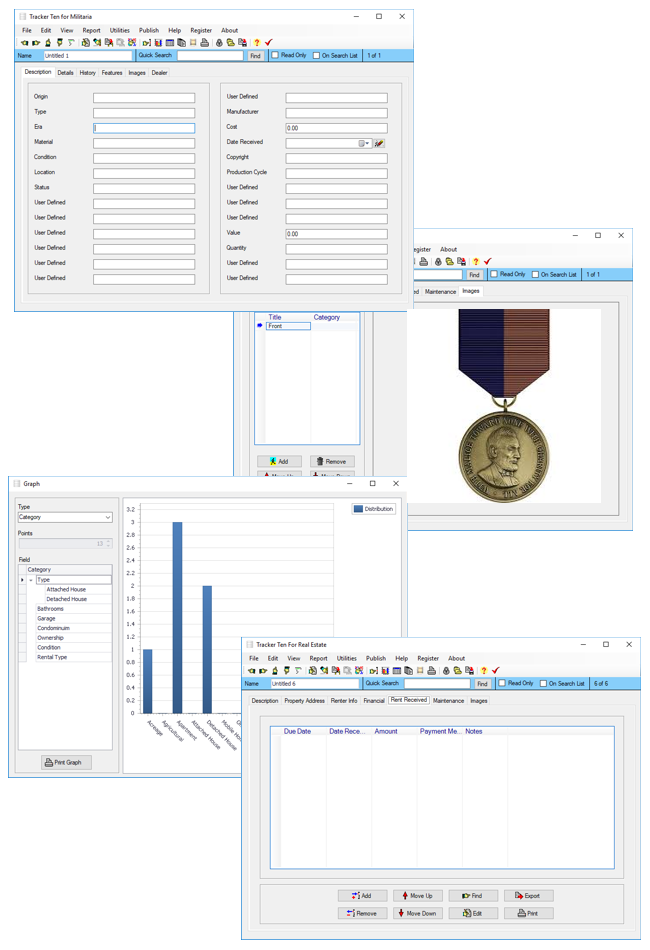

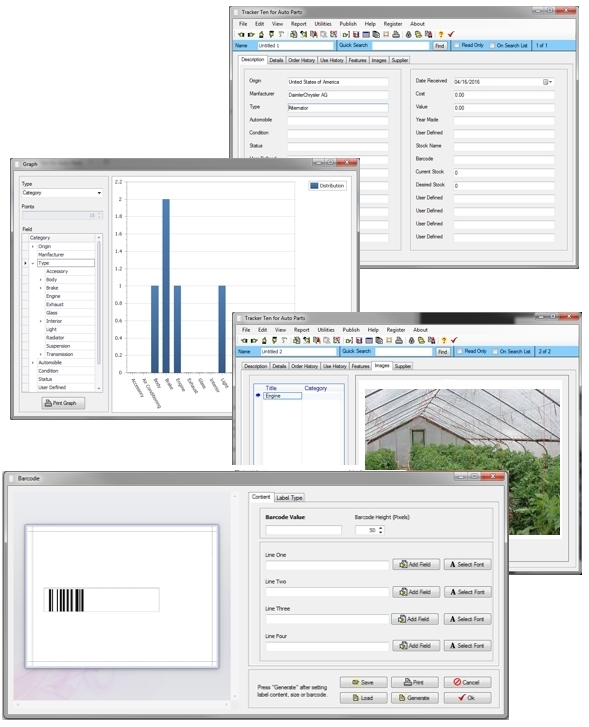

Stockroom Inventory Database Software

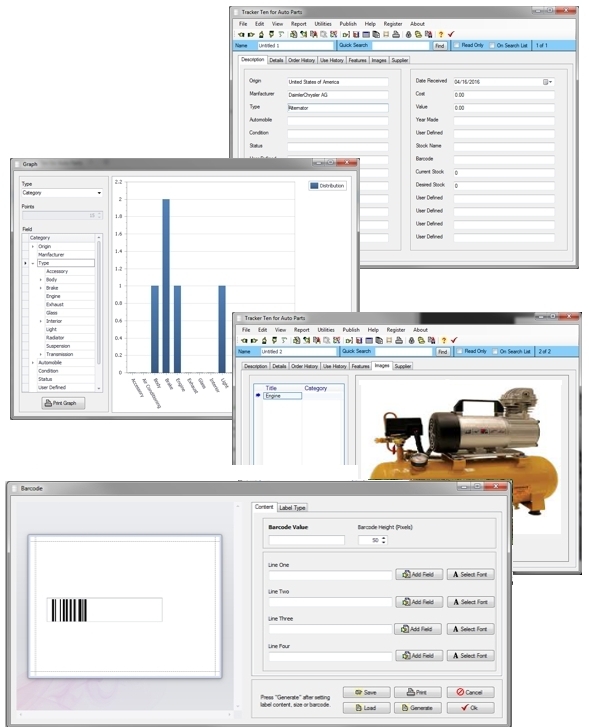

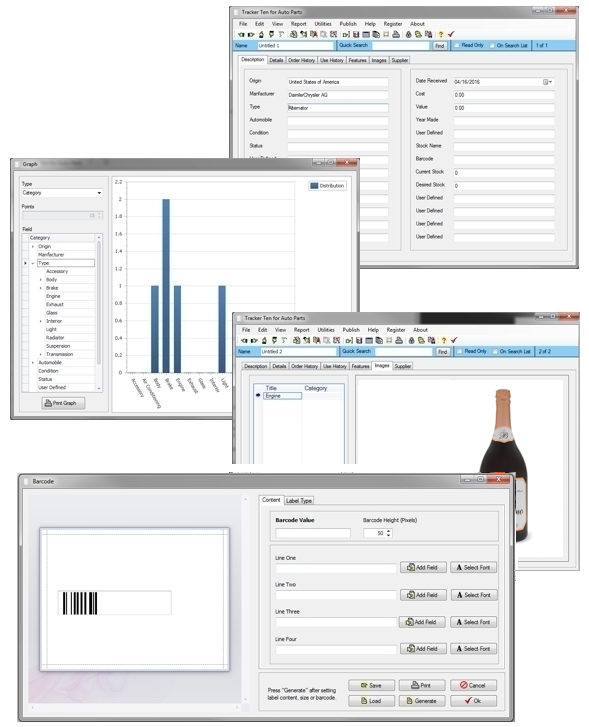

Modern stockroom management benefits greatly from specialized inventory software. Products like Tracker Ten for Stock Rooms help track incoming and outgoing items, monitor stock levels, and generate detailed reports. For more advanced needs, Tracker Ten Inventory Control provides features such as automated reorder alerts, analytics, and integration with barcode scanning systems.

Custom inventory solutions can also be developed to suit unique business needs. Contact us for tailored software solutions that address specific challenges, such as multi-location tracking, cold storage integration, or complex SKU hierarchies.

Stockroom Inventory Insurance

Stockroom inventory insurance protects a business against risks such as theft, fire, vandalism, or natural disasters. This insurance ensures that businesses can recover financially in case of inventory loss, which is critical for retailers, manufacturers, and wholesalers who rely heavily on their stock.

When selecting insurance, businesses should consider coverage limits, deductibles, exclusions, and the valuation method used for inventory. Comprehensive insurance policies help businesses maintain continuity, protect investments, and avoid financial hardship from unexpected losses.

Implementing effective stockroom insurance, combined with sound inventory management practices, ensures that businesses are well-protected and resilient against operational risks.

Looking for windows database software? Try Tracker Ten

- PREVIOUS Data Intelligence Thursday, December 26, 2024

- NextIn Memory Databases Friday, December 20, 2024