Database

Equipment Maintenance Tracking

Equipment maintenance tracking is the systematic process of recording, monitoring, and analyzing maintenance activities for machinery, tools, vehicles, and other equipment. Its primary goal is to ensure equipment operates efficiently, safely, and cost-effectively. Maintenance tracking allows organizations to prevent unexpected downtime, identify recurring issues, and optimize maintenance schedules by maintaining a comprehensive history of all maintenance activities. This practice is essential across industries including manufacturing, healthcare, construction, transportation, and energy production.

At its core, equipment maintenance tracking involves logging detailed information about each piece of equipment, including purchase date, operational status, scheduled maintenance, repairs, replacement parts, and downtime. By analyzing these records, organizations can anticipate potential failures, extend equipment lifespan, improve safety, and make data-driven decisions about repair versus replacement. With the growth of digital technologies, many organizations now use software tools, such as Computerized Maintenance Management Systems (CMMS) and Enterprise Asset Management (EAM) platforms, to automate tracking, reporting, and analytics.

There are numerous benefits to implementing equipment maintenance tracking, including improved equipment reliability, reduced operational costs, minimized downtime, regulatory compliance, and enhanced employee safety. Organizations that neglect maintenance tracking often face higher costs due to unexpected failures, inefficient use of resources, and reduced productivity. By proactively monitoring equipment, organizations can maximize operational efficiency and protect both human and financial resources.

Equipment Safety

Safety is a critical reason for tracking equipment maintenance. Poorly maintained equipment can malfunction, causing workplace accidents, injuries, or even fatalities. By systematically recording maintenance activities and inspections, organizations can identify safety risks early and take corrective action before incidents occur. Maintenance tracking not only safeguards employees but also minimizes liability risks and protects the organization’s reputation.

Key ways that equipment maintenance tracking enhances safety include:

Preventive Maintenance: Scheduled maintenance reduces the risk of equipment failure by proactively addressing wear and tear, lubricating moving parts, and replacing worn components.

Equipment Inspections: Routine inspections detect hazards such as loose or damaged components, electrical issues, and potential mechanical failures. Tracking inspection results ensures timely corrective action.

Repair History Analysis: Monitoring repair history helps identify equipment that frequently fails or is prone to specific problems, enabling organizations to replace or upgrade unsafe machinery.

Employee Training: Maintenance records highlight areas where operators may require additional training, reducing the risk of misuse and enhancing overall safety culture.

Compliance Monitoring: Documenting safety checks and maintenance ensures adherence to workplace safety standards and regulatory requirements.

By integrating safety-focused maintenance tracking into standard operating procedures, organizations can create a proactive safety culture, reduce workplace accidents, and ensure operational continuity.

Equipment Inspections

Equipment inspections are a cornerstone of effective maintenance tracking. Inspections involve detailed assessments of machinery to identify wear, potential failure points, and compliance with operational standards. They are essential for preventing accidents, reducing downtime, and extending equipment life.

Important aspects of equipment inspections include:

Types of Inspections: Pre-operational inspections are conducted daily or per shift to ensure equipment is ready for use. Routine inspections occur weekly or monthly to identify emerging issues, while periodic inspections involve comprehensive evaluations for long-term reliability.

Inspection Procedures: Visual checks, functional tests, measurement of mechanical tolerances, and safety feature verification are standard procedures. Inspections may include disassembly for detailed evaluation when necessary.

Documentation: Records should include the date, inspector name, findings, and corrective actions. Maintaining accurate records allows for trend analysis and ensures accountability.

Importance of Compliance: Inspections ensure that equipment meets safety regulations and operational standards, reducing the risk of accidents, regulatory fines, and liability issues.

Predictive Insights: Inspection data can reveal early signs of component fatigue, enabling preemptive maintenance and reducing unexpected failures.

Regular, documented inspections form the backbone of maintenance tracking and contribute to improved reliability, safety, and cost savings.

Legal Compliance and Equipment Tracking

Maintaining accurate records of equipment maintenance is often a legal requirement. Regulations in industries such as healthcare, aviation, construction, manufacturing, and transportation mandate regular inspections, testing, and maintenance. Non-compliance can lead to fines, legal action, or operational shutdowns.

Regulatory Compliance: Maintenance tracking demonstrates adherence to industry standards, such as OSHA, ISO, FAA, or local environmental regulations. Organizations can produce records during audits or inspections to validate compliance.

Safety Compliance: Equipment failures pose a liability risk. By tracking maintenance schedules and repairs, organizations ensure that all equipment meets safety regulations, reducing legal exposure.

Record Keeping: Maintenance logs provide evidence of compliance, including inspection results, repair records, and preventive maintenance schedules. These records are crucial for internal audits and regulatory reporting.

Audit Readiness: Auditors often review maintenance documentation to ensure regulatory compliance. Systematic tracking ensures that records are organized, complete, and easily accessible.

Effective maintenance tracking protects organizations from legal liabilities and ensures compliance with applicable standards, safeguarding both employees and organizational reputation.

Saving Money with Equipment Maintenance Tracking

Maintenance tracking is not only a safety and compliance tool—it is also a major cost-saving strategy. Proactive maintenance reduces emergency repairs, extends equipment lifespan, and minimizes downtime, which directly impacts operational costs.

Preventive Maintenance: Regularly scheduled maintenance reduces the likelihood of unexpected failures, avoiding expensive emergency repairs and downtime.

Equipment Lifespan Extension: Maintaining detailed records ensures timely replacement of worn components, reducing premature equipment retirement and capital expenditure.

Downtime Reduction: Tracking performance and repair history allows for scheduled maintenance during off-peak hours, minimizing production disruptions.

Optimized Maintenance Schedules: Data-driven maintenance schedules prevent unnecessary work, reducing labor and material costs while improving operational efficiency.

Inventory Management: Tracking maintenance enables organizations to manage spare parts inventory efficiently, reducing overstock and obsolescence costs.

Energy Efficiency: Well-maintained equipment operates more efficiently, reducing energy consumption and associated costs.

Organizations that invest in maintenance tracking benefit from improved reliability, reduced costs, and enhanced operational performance.

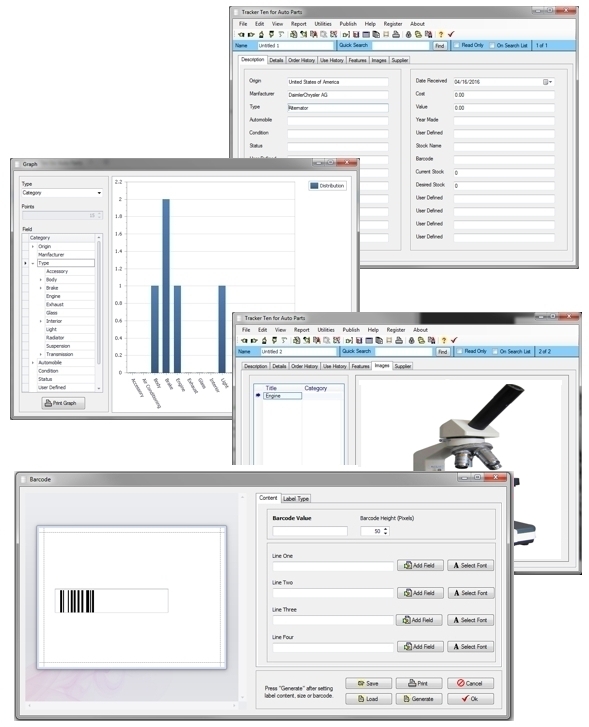

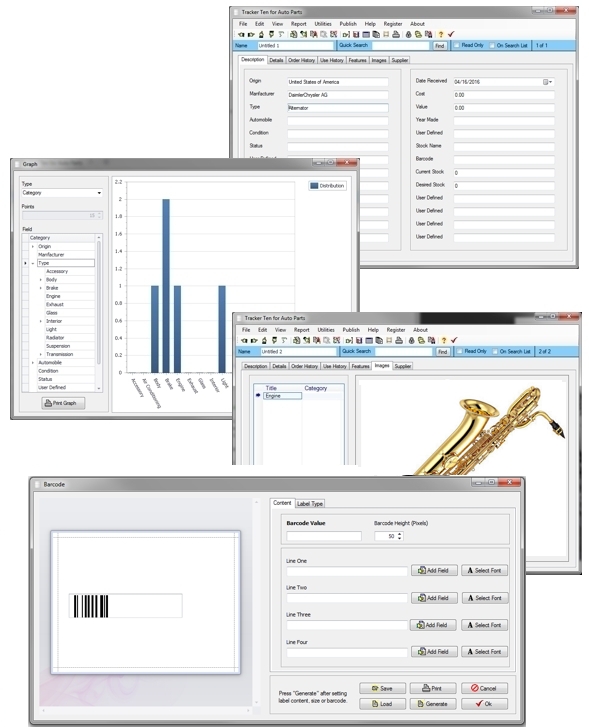

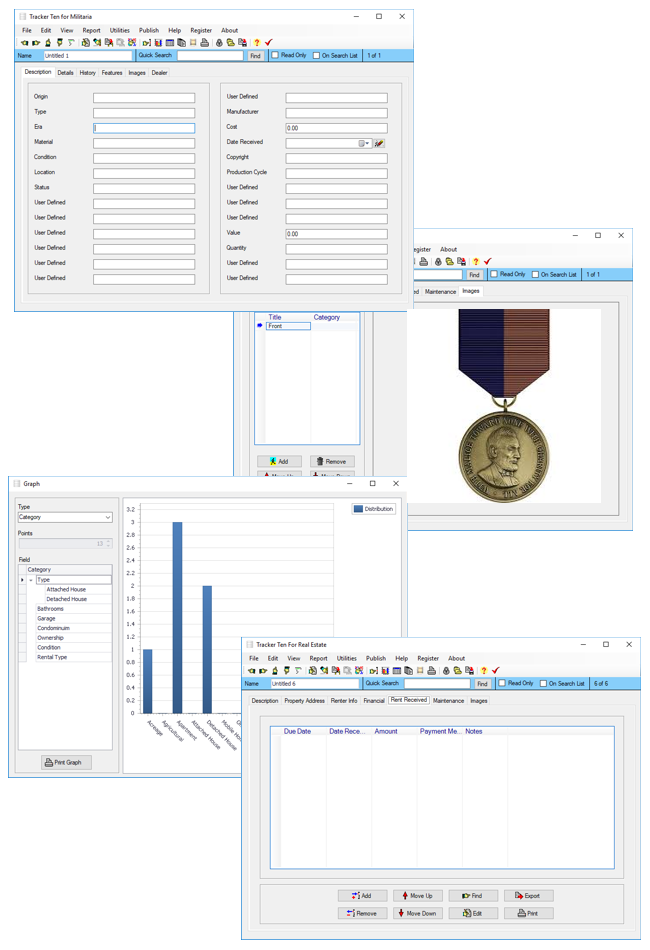

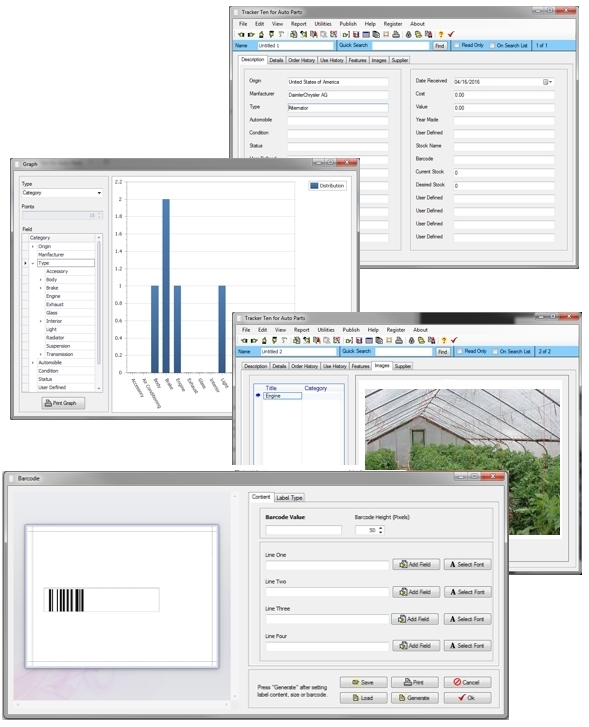

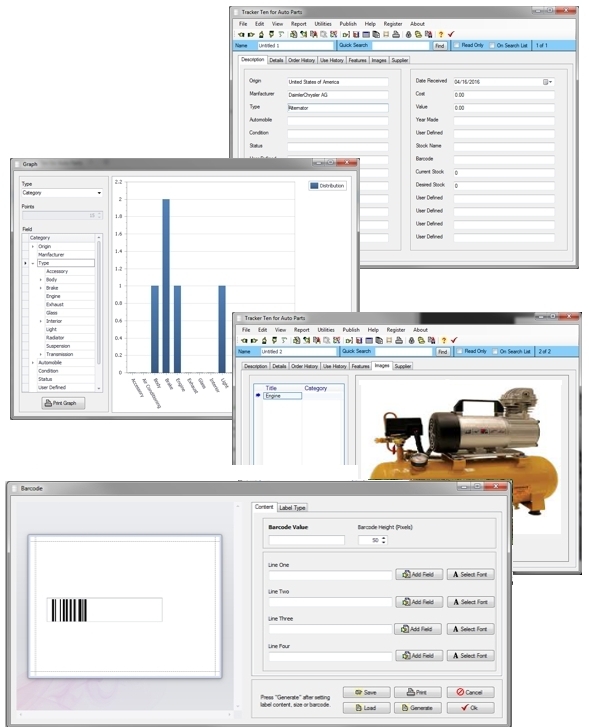

Equipment Maintenance Tracking Software

Modern software solutions make equipment maintenance tracking more efficient and accurate. Tools like CMMS and EAM platforms allow organizations to record maintenance schedules, track inspections, manage spare parts, and generate reports. These systems can include features such as automated reminders, predictive analytics, mobile access, and integration with IoT sensors for real-time monitoring.

Examples of popular software solutions include:

CMMS (Computerized Maintenance Management Systems): Centralized systems to schedule maintenance, track work orders, monitor downtime, and manage spare parts.

EAM (Enterprise Asset Management): Comprehensive platforms for managing all organizational assets, including equipment, facilities, and infrastructure.

IoT-Integrated Monitoring: Sensors and smart devices can feed real-time data into maintenance systems, predicting failures before they occur.

Mobile Applications: Enable maintenance personnel to update records, perform inspections, and track repairs on-site from mobile devices.

Analytics Tools: Analyze maintenance trends, costs, and equipment performance to optimize schedules and improve ROI.

If you are looking for software to streamline equipment tracking, our Tracker Ten for Equipment software provides detailed tools to manage maintenance schedules, inspection logs, and repair histories effectively.

Conclusion

Equipment maintenance tracking is a critical component of operational excellence. It ensures safety, legal compliance, cost savings, and optimal performance. By documenting inspections, repairs, and preventive maintenance, organizations can extend equipment life, reduce downtime, avoid costly failures, and maintain a safe work environment. Leveraging modern software solutions, data analytics, and proactive strategies transforms maintenance tracking from a reactive process into a proactive, strategic asset management tool. Organizations that implement effective tracking practices position themselves for long-term success, safety, and profitability.

Explore Tracker Ten for Equipment to implement a comprehensive equipment maintenance tracking system tailored to your organization’s needs.

Looking for windows database software? Try Tracker Ten

- PREVIOUS Tool and Hardware Tracking Database Software Thursday, June 15, 2023

- NextScientific Lab Equipment Sunday, June 4, 2023